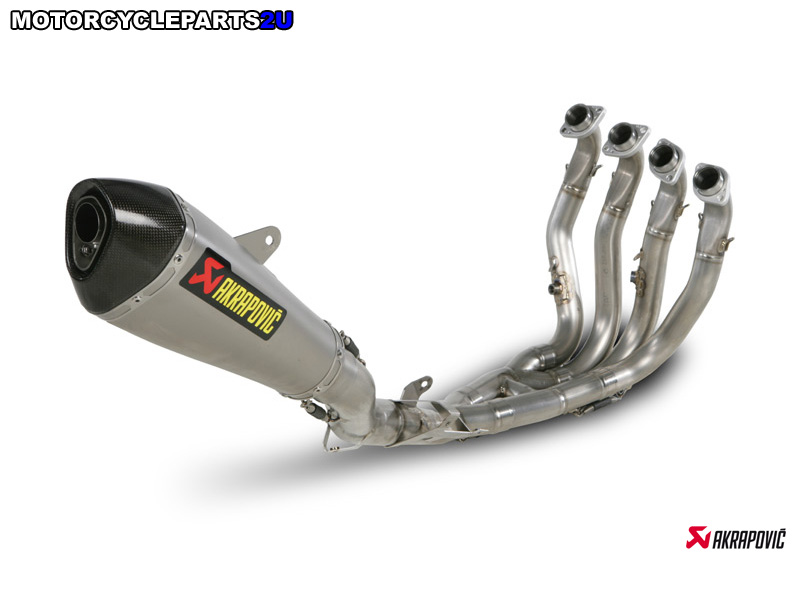

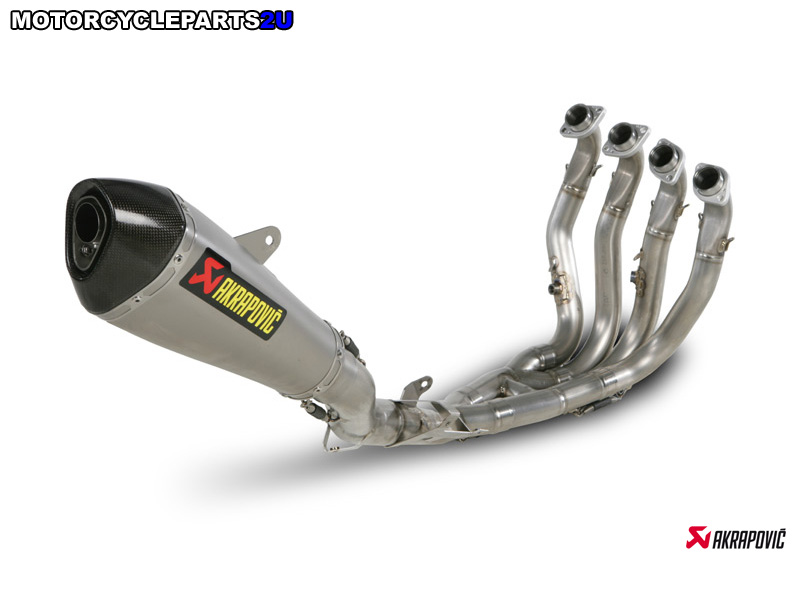

I have an Akrapovic Evo system on my bike, and I've always been curious about a certain design feature of the header pipe.

If you look at the image below, right where the header pipes make their bend out of the engine, the radius has an odd flat indentation which chokes down the diameter of the tube by a significant amount.

At first glance it looks very much like it's nothing but a restriction to maximum exhaust gas flow, but I think everyone knows that Akra has a pretty good idea of what they're doing so I assume only that it's some research design element that increases performance in SOME way, as it would be far simpler to make the bend a normal radius throughout.

Does anyone have an idea what the physics and theory is behind this choking down of the pipes the way they are? In my experience, Akrapovic is the only exhaust system manufacturer that does this.

Hopefully you can see it clearly in the image

If you look at the image below, right where the header pipes make their bend out of the engine, the radius has an odd flat indentation which chokes down the diameter of the tube by a significant amount.

At first glance it looks very much like it's nothing but a restriction to maximum exhaust gas flow, but I think everyone knows that Akra has a pretty good idea of what they're doing so I assume only that it's some research design element that increases performance in SOME way, as it would be far simpler to make the bend a normal radius throughout.

Does anyone have an idea what the physics and theory is behind this choking down of the pipes the way they are? In my experience, Akrapovic is the only exhaust system manufacturer that does this.

Hopefully you can see it clearly in the image