Well, that was a productive couple of weekends.

My wife was busy last weekend, and is gone this weekend, so I've gotten to put in some quality time with the RVFlette. The picture that Scott posted up a bit ago was of my first order from Graeme France over in the UK. Graeme has taken great care of us (Scott ordered a clutch of parts, too). Of all the parts I ordered, the most important is a wiring harness. The one on the bike was hacked all to shit, and there was no way I would be able to live with it. I also got a few other choice bits.

Last weekend, I tackled the brakes. The rear brakes had never really gotten any love from me. I did bleed them when I was doing the fronts, but I never pulled everything off and scrubbed like the bike deserves. I ordered a braided steel brake line and and HRC race brake reservoir tube (because racebike) from Graeme, so I figured it'd be a nice one-shot to install. Simple self-contained projects like that are great because they keep the motivation high. I don't have to find good stopping points or plan my work, and the effort levels is low; I just walk in, throw some parts on, and then take pictures (obviously).

Side note, I've probably spent 1/2 of the total time on this bike standing in front of the parts washer, scrubbing things nobody else will ever see. The rear brake caliper is a good example - it's buried on the bottom side of the wheel, up under the swingarm and nearly invisible at every angle. And yet I still pulled it off, scrubbed it shiny, wire-brushed all the bolts, and put it back.

Anyway, the entire brake system is now in a state that makes me happy... almost. I did struggle a little bit with the rear brake routing. You see, it's pretty common for people to actually drill a small hole in the swingarm and route the hose through it. Then you remove the chain guard. The result is pretty striking, actually - there's nothing but a wheel and a chain hanging out in space. I really want to do it, but I didn't want to try with the swingarm on the bike... so I ordered another swingarm.

That's going to have to wait, though... too much else to do.

Also on the list was clipons. Why? Well, it's a bit hard to see, but it's really easy to feel...

I really, really wanted to find some stock pieces. I like the RVF's ergonomics. It's sporty but not punishing, and I really wanted to preserve that, but short of paying

$211 each

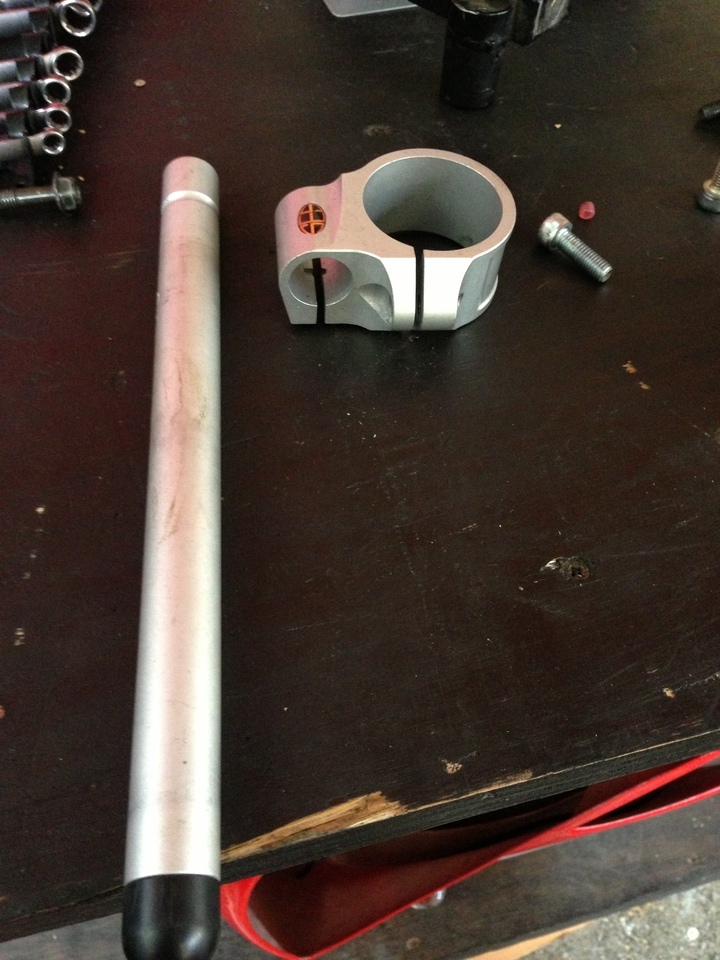

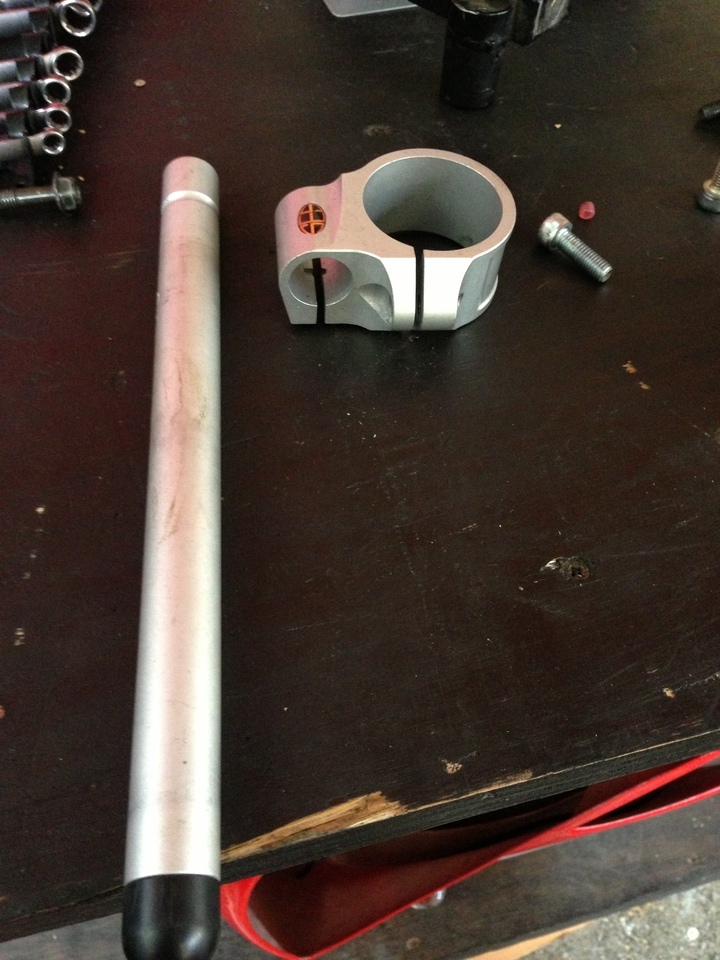

, I was going to have to go with aftermarket. Graeme recommended some British-made SES clipons. To be honest, I'm still not totally sold on them - I may end up replacing them with some Woodcraft 1" rise bars. Stock rise is about half an inch, but given how tight the clearance between the controls and the fairing already is, I figured it'd be safer to lower the bar a bit.

They're very high-quality pieces, that's for sure. The machining is really good, and they're super lightweight, which makes me happy. So, no complaints for now. We'll see if my back agrees when I try to take an extended ride up to Comptche-Ukiah, or out to the junction.

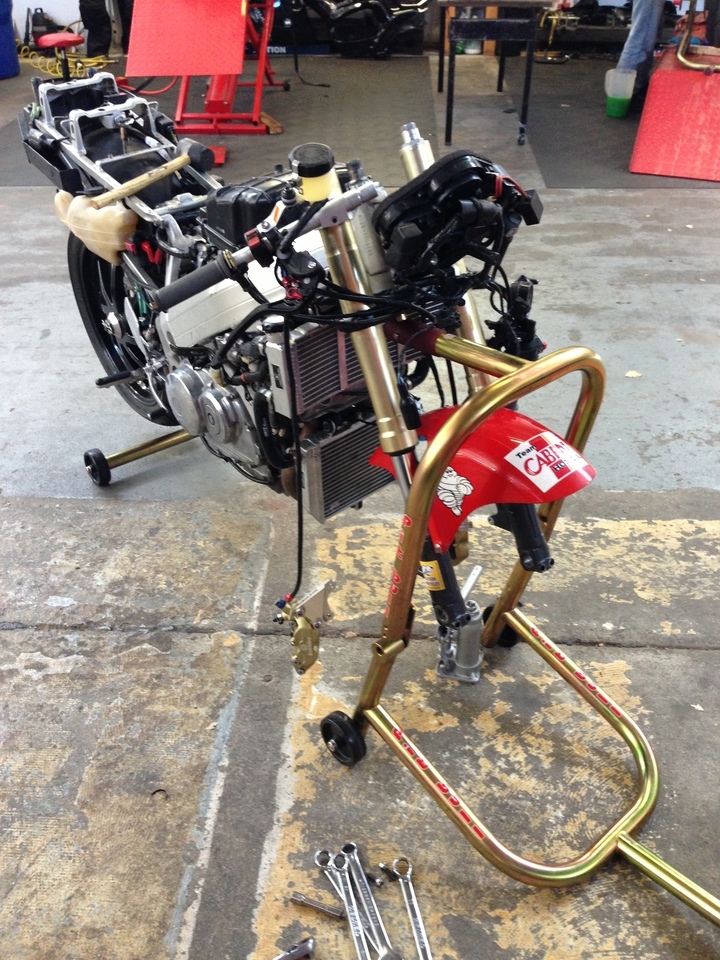

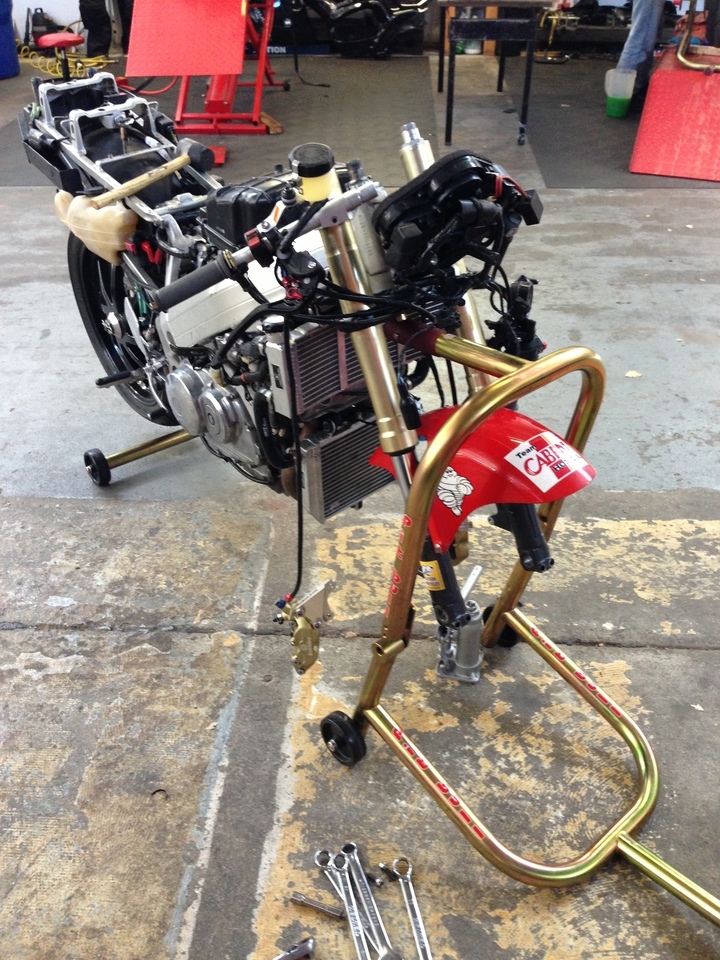

So, clipon swap. Easy, right? Er, no.

Seems like every damn time I want to do any damn thing to this damn bike, I have to take every damn thing apart. Pulling the clipons required pulling the top triple, which of course means that the lower triple flexed enough that I couldn't get the top triple back on, which means I had to pull the wheel, which means I had to pull the calipers, all so I could loosen the lower triple clamp bolts enough to slip the top triple back on. I guess that's why it's a project, right?

Installation is the reverse of removal, and installation is fun because... mmm tasty.

Okay, so in all fairness, I

did already have the tank and the tail plastics off because I had just finished swapping the wiring harness. It was actually not as hard a job as I expected. The undertail plastic is hacked to shit and all busted up, which changing the harness made obvious (so that's one more thing to order from the UK) but it otherwise went pretty smoothly. The bike has obviously had a pretty hard life - the generator/stator wiring was cut, the ignition wires were cut, and the left side switchgear pretty clearly has some sort of issues, but everything else was in acceptable condition. Mostly, it makes me incredibly happy for every wire to be in its right place, and wrapped by the factory.

If you'll recall this picture from May...

This is roughly the same shot from today (please excuse the lighting)...

Could I have built my own harness that would be even better than Honda's?

Of course. I've done it. And it cost hundreds in wire and plugs and hours and hours of reading data sheets and construction. This lets me hit all my OCD relief buttons and I don't have to DIY. Yes please.

I also did some other, minor things. The carbs hadn't been synced, so I did that to much improvement. I'm still not totally happy with how the bike runs, but I suspect needles and springs will fix that. Or maybe not. I've got to schedule some dyno time, come to think of it... I also fixed the radiator fan, though it'll have to have a manual switch for a while until I get some new radiators to replace the horrible, shit Chinese eBay specials I have now.

Holy shit, wait, if the wiring harness is done, and it's

tested and working

tested and working

, and the carbs are sync'd, I guess it's time to button it up in earnest. This is the first time the bike has had its lower fairing on in months...

anyway

anyway

Once that was done, it was time to see if it started and ran any better than it did the first time, when it had so many crazy intake leaks...

Once that was done, it was time to see if it started and ran any better than it did the first time, when it had so many crazy intake leaks...

, I was going to have to go with aftermarket. Graeme recommended some British-made SES clipons. To be honest, I'm still not totally sold on them - I may end up replacing them with some Woodcraft 1" rise bars. Stock rise is about half an inch, but given how tight the clearance between the controls and the fairing already is, I figured it'd be safer to lower the bar a bit.

, I was going to have to go with aftermarket. Graeme recommended some British-made SES clipons. To be honest, I'm still not totally sold on them - I may end up replacing them with some Woodcraft 1" rise bars. Stock rise is about half an inch, but given how tight the clearance between the controls and the fairing already is, I figured it'd be safer to lower the bar a bit.